LED linear lighting has become a standard choice for residential, commercial, and architectural applications. Whether you are building accent lighting for a retail shelf or adding ambient illumination to a living space, two common options usually appear in your toolkit: flexible tape lights and rigid light bars.

Although both are designed for linear illumination, the internal structure, performance output, and installation flexibility differ greatly. Choosing the right product requires understanding how they behave under real use cases — from bend radius to thermal performance to lumen density.

Below is a deep dive into how these two systems stack up.

Flexible tape lights are built on a bendable PCB (usually 2–10 oz copper), allowing them to contour along arcs, irregular surfaces, or tight spaces.

Typical specifications:

PCB thickness: 0.2–0.35 mm

Bend radius: as low as 20–30 mm

Weight per meter: approx. 20–35 g

Cut length: 25 mm / 50 mm / 100 mm depending on LED density

IP rating options: IP20–IP67

Their ability to bend makes them suitable for indirect lighting, cove lighting, display shelves, and decorative contour applications. Products like RGBW LED Flexible Tape Light and High CRI Flexible Tape Light are widely used where color performance and softness matter.

Rigid bars use an aluminum or FR4 base PCB. They are straight, durable, and offer excellent thermal dissipation.

Typical specifications:

PCB thickness: 1.0–1.6 mm

Integrated aluminum housing or extrusion

Higher thermal conductivity

Cut length: usually 250 mm / 500 mm / 1000 mm

Weight per meter: 120–300 g depending on housing

These are ideal for environments where stability and long-term performance matter, such as light boxes, industrial machines, and under-cabinet task lighting.

This is one area where significant differences appear.

| Specification | Flexible Tape Light | Rigid Light Bar |

| Lumens per watt | 90–105 lm/W | 110–130 lm/W |

| Max LED density | 180–528 LEDs/m | 72–144 LEDs/bar |

| Heat dissipation | Moderate | Excellent |

| Long-term lumen maintenance | 80–85% @ 10,000h | 88–92% @ 10,000h |

Rigid bars commonly outperform tape lights in brightness, thermal management, and lumen maintenance, especially for high-power LEDs. Flexible strips designed for high output — such as High Brightness Flexible Strip Lights — are now closing the gap, but still rely heavily on the installation surface for heat dissipation.

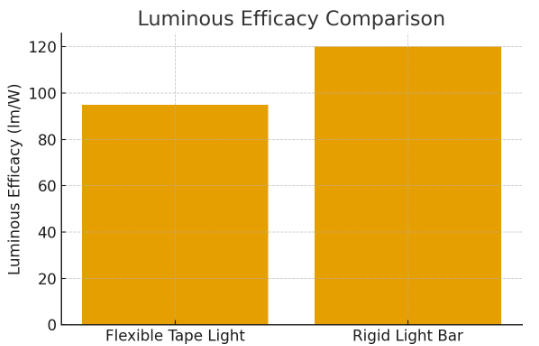

The chart provides a visual comparison showing that rigid bars often deliver higher lm/W because of better heat flow and larger copper area.

High-end interior projects such as retail, galleries, cosmetics counters, and residential hospitality lighting increasingly rely on CRI 95+ solutions.

High CRI Flexible Tape Light is common because designers prefer a continuous, shadow-free effect.

Rigid bars can reach similar color quality, but are used less in visible installations and more in task lighting.

For dynamic lighting:

RGBW LED Flexible Tape Light provides smooth, dot-free mixing, suitable for cove lighting, bars, and event spaces.

Rigid RGB bars exist but are more used in signage and outdoor wall-washing where beam angle requirements are strict.

Flexible strips dominate the decorative and architectural RGB market simply due to their bending capability and installation convenience.

| Factor | Flexible Tape Light | Rigid Light Bar |

| Ease of installation | Very easy (adhesive backing) | Requires screws/clips |

| Can be bent | Yes | No |

| Works on curved surfaces | Excellent | Poor |

| Task lighting | Moderate | Excellent |

| Decorative/ambient lighting | Excellent | Moderate |

| Industrial durability | Low–Medium | High |

Flexible tape lights are the clear winner when:

The surface is curved, narrow, or irregular

You need soft lighting or hidden installations

Running long continuous lengths

Rigid bars are ideal when:

Heat management matters

High lumen output is required

The environment involves vibration, heat, or long duty cycles

Straight, precise lighting lines are needed

Rigid light bars offer:

Aluminum substrate (MCPCB) for superior heat transfer

Strong mechanical resistance

Longer LED lifespan due to cooler junction temperature

Flexible strips:

Rely heavily on the mounting surface for heat dissipation

Can degrade faster when driven at higher power

Are sensitive to bending stress over time

For 24/7 operations or industrial settings, rigid bars maintain around 10–15% lower thermal rise, which correlates directly to longer LED life.

| Cost Factor | Flexible Tape Light | Rigid Light Bar |

| Material cost | Low | Medium–High |

| Thermal materials | Minimal | Required |

| Installation cost | Low | Medium |

| Driver requirements | Same | Same |

Tape light cost per meter is usually 30–50% lower, which explains why they dominate architectural LED lighting projects.

Instead of one being universally better, the right choice depends on application:

Continuous, dot-free ambient lighting

RGBW or tunable effects

High CRI lighting for interiors

Complex shapes, indirect coves, retail shelves

A cost-effective linear solution

Products like High CRI Flexible Tape Light or High Brightness Flexible Strip Lights for visual-critical areas

Maximum brightness

Strong structural stability

Long duty cycles or industrial environments

Excellent thermal management

Straight, high-intensity task lighting